Applying the horizontal drilling method - rotating with a set of conduit samples at Minh Phuong mining enterprise

Especially, in the past time, underground mining enterprises have applied the technology of drilling conduits to take samples in horizontal boreholes using RPD - 75 SL equipment.

Ngày đăng: 30-08-2021

1,646 lượt xem

One of the major challenges facing the mineral industry is the difficulty in providing the ore processing plant with specifications of levels that match its good performance. Knowledge of the geology of the various lithographs that form a deposit is a fundamental step in ensuring the expected quality of the ore, but it is not sufficient. After knowing the various fields of geology, covering a wide range of exploration activities and whose final product is a three-dimensional solid model, obtained with the use of geostatistical techniques, an important activity Equally important is the estimation of the content, level properties of the variables of interest for each block through interpolation techniques such as kriging. This article contains a comparative analysis of estimates of content obtained by three different types of sampling for mining quality control and presents the results of a practical application of an enterprise case study. mining in Vietnam.

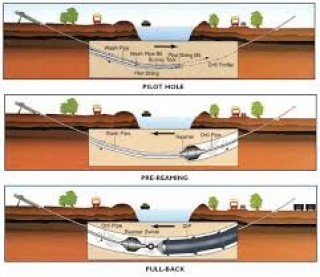

Currently, some mining enterprises, particularly coal mining, have actively applied forward drilling technology to solve underground mining problems. Since 2002, according to the results of the research cooperation project "applying water burst prevention technology in underground coal mines of Vietnam" between the Institute of Mining Science and Technology and JCoal (Japan); The Japanese side has introduced two types of drilling equipment in the pit: PPn - 2 and RPD - 75SL. In particular, the horizontal drilling equipment RPD - 75SL is a modern rock drilling device capable of drilling horizontal, upper and lower oblique drilling in solid rock with a bore length of up to 150 m, hole diameter of 150 mm, a diameter of 150 mm. 65 mm finish glass. Especially, in the past time, underground mining enterprises have applied the technology of drilling conduits to take samples in horizontal boreholes using RPD - 75 SL equipment.

1. Advantages of threaded pipe drilling technology

During the mining phase, more granular sampling is needed to establish control levels, whose goals can be very diverse, such as improving the accuracy of long-term estimation models, where information obtained from samples of exploration, discovery, in ores, possible presence of areas of low level, etc. At this stage, diamond rotary probe samples, channel samples, volumetric samples from the mining front or drill powder samples can be used. All such actions will depend on available technology or financial resources.

In general, the conduit drilling technology has advantages compared to the traditional drilling technology as follows:

- Increased accuracy by increasing sample rate.

- Increase drilling speed, increase drilling productivity

- Reduce time and labor for drillers.

2. Technical characteristics of the PS - 89 H conduit set for horizontal drilling in the pit

Synchronously synchronously threaded sample pipe in the tunnel, including technological tools: Column to be drilled, sample pipe set, drill bit; Auxiliary tools such as: a set of catchers, a set of seals for the mouth that needs to be drilled when releasing the sample tube set and the sample tube holder; winch and pulley pulley pull the sample tube by cable; and tools to rescue the boom in the borehole.

Table 1: Technical characteristics of the PS - 89 H horizontal drill pipe set.

|

Parameters |

Unit |

PS - 89 H |

|

Outside diameter of drill |

mm |

101 |

|

Inner diameter of drill |

mm |

45 |

|

Outside diameter of sample tube outside |

mm |

89.1 |

|

Outside diameter of sample tube |

mm |

63.5 |

|

Outside diameter of sample tube |

mm |

60.5 |

|

Sample tube inner diameter |

mm |

50.5 |

|

Outside diameter of drill pipe |

mm |

89.1 |

|

Inner diameter of drill pipe |

mm |

63.5 |

|

Weight of sample tube set |

kg/m |

65 |

|

Length of sample tube set |

mm |

- |

|

Drilling weight |

kg/m |

17.5 |

|

Drill rod length |

mm |

1500 |

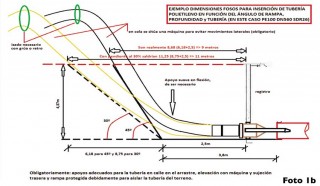

The working principle of the horizontal drill pipe set is similar to the vertical drill pipe set. The only difference is that when dropping the sample tube set and the salvage capture kit into the borehole by the pressure of the wash water pumped by the pump, the drilling mud cleaning solution. Therefore, the sample tube set and the pick-up hood are fitted with a pressure-resistant rubber ring; the diameter of the rubber ring is equivalent to the inner diameter of the column to be drilled, thus creating a push to force the sample tube set or the scoop set (when releasing the scoop) to the bottom of the borehole by the pressure of the pump wash water. from the liquid pump. Currently, the PS - 89 H horizontal drill pipe sample set has been tested for sampling and draining at the furnace level - 80 in the coal mining enterprise. Technical characteristics of the PS - 89 H horizontal drill pipe set, see Table 1.

The equipment used for horizontal drilling is the RPD - 75 SL rotary hammer; the beating mechanism is arranged at the top of the machine. Therefore, the drill bit used with the horizontal drill pipe set is the type of sampling drill used in punching - rotating drilling. To pull the sample tubes in the column to be drilled, use a hydraulic motor-driven SUS 304 winch; pull cable diameter 5mm.

3. Applying the horizontal drilling method with the PS - 89 H . conduit set

The PS - 89 H conduit sample set was drilled with RPD - 75 SL equipment at the furnace level - 80 mining enterprises. From the actual results, the following observations can be drawn:

a. The test hole was drilled horizontally, with an angle of 3150 in the direction of the hole with the furnace wall. From 0 - 10 m, drilled to break the sample with a drill with a diameter of 127 mm and placed a pipe with a diameter of 114 mm, fixed with cement. wall pipe with bore wall. Then move on to drill the PS - 89 H threaded sample pipe to a depth of 32 m. Drilling technology mode see Table 2.

Table 2. Parameters of drilling mode with conduit PS - 89 H

|

Soil |

Pn |

Px |

Pd |

Pr |

|

Coal claystone |

0.8 - 1.2 |

0.7 - 1.0 |

- |

0.6 - 0.8 |

|

Solid crystalline powder |

1.0 - 2.0 |

1.5 - 3.5 |

3.0 - 4.0 |

0.4 - 0.6 |

|

Solid sandstone and gravel |

2.0 - 3.5 |

3.0 - 4.0 |

4.5 - 6.0 |

0.4 - 0.6 |

Note: Pn - Compression force, MPa; P¬x - Rotation force, MPa; Pd - Thrust force, MPa; Pr - Wash water pressure value, MPa.

Blowing the drilling mud with cold water, the selected wash water flow depends on the rock's physical and mechanical properties; in the specific case of the borehole at the level furnace - 80 Mao Khe mine, the flow rate of the blower pump during the drilling process ranges from 25 l/min, to 45 l/min.

The speed and pressure transmitted to the rotary drill are the basic parameters that determine the rock breaking capacity. Horizontal drilling equipment RPS - 75 SL is arranged with two pressure transmission mechanisms for rock breaking drill bits: Pressure transmission by hydraulic system combined with chain transmission and striking force (damping energy) by mechanism dam installed at the top of the drill (top dam). As a result, when drilling solid rock, two forces are combined for the drill bit: the static force is transmitted from the hydraulic system and the dynamic force is transmitted from the dam mechanism. When drilling soft rock in the form of compressed clay, coal only needs to transmit static pressure from the hydraulic system.

The selected rotational speed depends on the rock mechanical properties and the method of pressure transfer to the drill bit. In the case of drilling for soft rock in the form of compressed clay or coal and the pressure transmitted to the drill bit from the hydraulic system, the rotational speed can be selected from 500 rpm to 900 rpm. In the case of drilling solid rock in the form of sand and grit combined with the impact force, the tool rotation speed is selected from 150 rpm to 200 rpm.

b. The mechanical speed of drilling in the solid sandstone and gravel strata reaches from 12 m/h to 13 m/h, which is much higher than the traditional drilling capacity. Core samples calculated for each drilling session (each session is 1.5 m long) averaged from 97% to 98%.

c. In horizontal drilling technology, special attention is paid to the process of dropping the sample tube set and the scoop into the borehole by the pressure of the wash water pumped directly by the drilling mud blower pump. In order to put the sample tube set and the scoop set into the borehole, a special tool kit is required to seal the mouth of the drill rod. Pump mode to push the sample container and the capture unit: pump flow 50 l/min to 70 l/min; push pressure 2 - 3 MPa. Then the movement speed of the sample tubes in the column to be drilled: 0.55 m/s to 0.84 m/s; The movement of the catcher is from 0.5 m/s to 0.7 m/s.

d. The test hole ended at a depth of 32 m, (the expected ending depth was 80 m; but due to the coal seam and water stored in the furnace wall, it penetrated into the borehole and collapsed uncontrollably). After the borehole is finished, a system of valves and gauges has been installed to measure the water pressure coming out of the borehole. Measurement results show that water flows out from the borehole with a flow rate of 3 l/min.

4. Conclusion

Up to now, although drilling in the pits is in the stage of testing and selecting a reasonable technology, it has also achieved certain results in the field of additional exploration and accurate data. geology and contribute to solving some problems in the safety area to prevent water burst incidents in the pit by drilling ahead to drain the water. Therefore, in the future, it is necessary to deploy applications to serve the purposes of mining technology and improve safety in underground mines.

Learn more Safety during construction stage

CÔNG TY CP TƯ VẤN ĐẦU TƯ VÀ THIẾT KẾ XÂY DỰNG MINH PHƯƠNG

Địa chỉ: 28B Mai Thị Lựu - Khu phố 7, Phường Tân Định, TP.HCM

Hotline: 0903 649 782 - 028 3514 6426

Email: nguyenthanhmp156@gmail.com

Website: www.minhphuongcorp.com - www.minhphuongcorp.net